Description

Plaster of Paris is a very popular chemical substance that is mostly used for sculpting and also in gauze bandages. We all know that the plaster of Paris is used by doctors to support fractured bones, it is also used in the construction industry, in making casts for statues and making designs for ceilings.

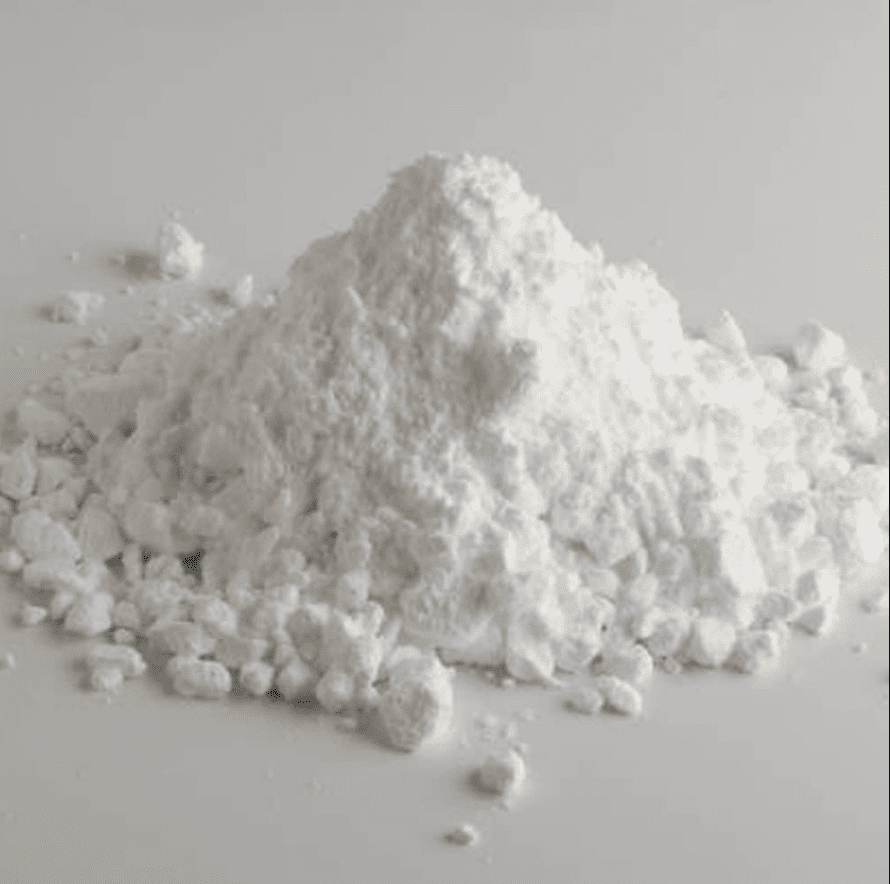

There are many uses of Plaster of Paris in our day to day life. Plaster of Paris is a white color powder that is nothing but hydrated Calcium Sulfate and it is obtained from Calcining Gypsum. In order to obtain Plaster of Paris, Calcining Gypsum is heated at a very high temperature.

The plaster of Paris has a remarkable property of setting with water. On mixing it with an adequate amount of water, it forms a plastic mass that gets into a hard solid in 5 to 15 minutes. The Plaster of Paris name has been used since ancient times because of the abundant preparation of Gypsum found near Paris.

Properties of Plaster of Paris

There are two main properties of Plaster of Paris:

Plaster of Paris is non-flammable as well as non-combustible as it has a low chemical reactivity. In extreme conditions, it also acts as an oxidizing agent. Plaster of Paris has fire resistance quality and its material is ideal for heat insulation. The material does not shrink when it sets. Hence, there are no cracks on the surface of the dry Plaster of Paris. At high temperatures, the plaster of Paris also decomposes and becomes toxic oxides.

Characteristics of Plaster of Paris

Plaster of Paris is easy to spread

It is non-flammable

It forms a very thick surface and can resist normal knocks after drying.

It does not expand much on setting

Plaster of Paris is a dry white powder and can be effectively worked with metal or even sheets and it can be molded as desired. It is applied in the form to enable quick setting using water. Water when added, Gypsum crystals are formed in order to achieve the solid-state.

Types of Plaster of Paris

Gypsum Plaster

This plaster is made by heating Gypsum at 120 to 180℃. Gypsum Plaster is used for setting fractured bones by doctors in hospitals. It is also used by dentists for preparing casts. There is a variety of toys and decorative items available made out of Gypsum Plaster. It can be used as a fire-proof material as well due to its fire-resistant quality.

Clay Plaster

The Clay Plaster is made by mixing clay, sand and water along with plant fibers. Clay Plaster is also used in making the interiors of a house. The use of Clay Plaster is not as much as it was in the early Nineteenth century in Utopian villages.

Lime Plaster

The Lime Plaster is made by mixing Calcium Hydroxide and Sand. When the plaster comes in contact with the Carbon dioxide in the air it transforms into Calcium Carbonate. This plaster is made by heating limestone or Calcium carbonate above the temperature of

850∘C.

Cement Plaster

The Cement Plaster is made by mixing suitable plaster, sand, water and Portland cement. The Cement Plaster was also known as Adamant Plaster. This was mainly used to obtain a smooth surface while building construction. Cement Plaster is used for its properties of strength and durability. In construction, there is a layer of Gypsum Plaster added on top of the Cement Plaster.

Heat Resistant Plaster

The Heat Resistant Plaster is most commonly used for coating walls and chimneys. It is used to resist fire. The Gypsum plasters have been replaced with Heat Resistant Plaster as it can stand very high temperatures in comparison with Gypsum Plasters.

Now, let’s understand the preparation of the plaster of Paris.